Dillon 650 Flare Without Powder Feed

As good as the Dillon reloading machine line is, I still look to find ways to improve perfection. All Dillon 650 owners have been plagued by the issue of powder flying from cartridges as the shellplate forcefully snaps into its index. This harsh indexing, not by bad design, is an issue that can easily be fixed by modifying the index spring and by adding a little goodie by Hit Factor.

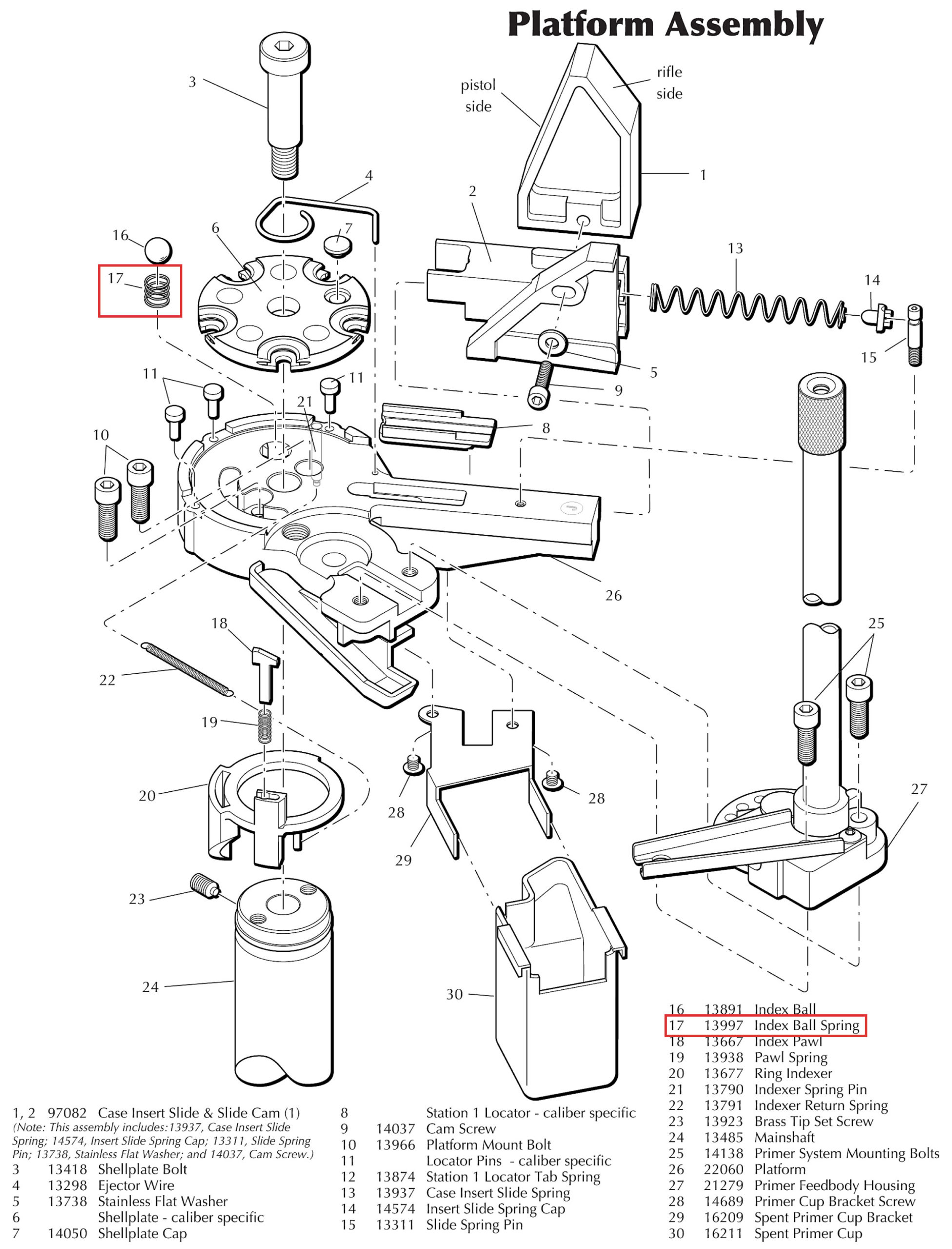

When Dillon 650 newbies go to spin that shellplate for the first time, they will be left scratching their head in frustration at all the spilled powder. This problem is a result of a spring that sits under the index ball; the ball that indexes the shellplate as it spins with every handle pull. This forceful indexing can cause powder to fly out of cartridges or misaligned rounds that can be jammed into dies causing damaged brass or even worse, damaged dies. By simply trimming this spring and adding the Hit Factor Shellplate Bearing Kit, you can alleviate these issues. Not only does it resolve troublesome issues, it can also improve the tolerances of your rounds.

Trimming the Index Ball Spring

When I first purchased the Dillon 650 several years back, I called Dillon regarding this issue and they recommended trimming the Index Ball Spring (Part #: 13997). The most IMPORTANT part of this process is to trim in small increments. Even though Dillon offers a replacement spring, it will cost you $10.44 with shipping.

In the below steps, the numbers in parentheses reference the part numbers in the Dillon 650 platform assembly diagram.

Step 1

Raise the Platform to Expose the Set Screw

Lower the handle to raise the platform to expose the main shaft (24) set screw (23).

Step 2

Remove the Shellplate Bolt

With the setscrew (23) loosened it will allow the shellplate bolt (3) to be removed.

Step 3

Remove the Ejector Wire and Shellplate

With the shellplate bolt (3) removed take off the ejector wire (4) and shellplate (6).

With the shellplate (6) off this will reveal the index ball (16).

Step 4

Remove the Index Ball and Index Ball Spring

Pop the index ball (16) out to allow removal of the index ball spring (17). A small allen wrench will do the trick.

With the index ball spring (17) out trim the spring in small increments.

*REMEMBER trim the spring in small increments. After each trim reinstall all components and test the shellplates indexing until the indexing is smooth.

Step 5

Installing the Hit Factor Dillon 650 Shellplate Bearing Kit

The Hit Factor bearing kit is a roller bearing unit that is sandwiched between two washers that sits in between the shellplate and shellplate bolt. This component allows for the shellplate bolt to be tightened providing for better support of the shellplate. This snug fit allows for less runout and a more consistent priming. Also, another advantage of this add-on is that it will not void your Dillon warranty since you are not modifying any of the original components. You can buy the bearing set from Hit Factor.

As good as the Dillon reloading machine line is, I still look to find ways to improve perfection. All Dillon 650 owners have been plagued by the issue of powder flying from cartridges as the shellplate forcefully snaps into its index. This harsh indexing, not by bad design, is an issue that can easily be fixed by modifying the index spring and by adding a little goodie by Hit Factor.

When Dillon 650 newbies go to spin that shellplate for the first time, they will be left scratching their head in frustration at all the spilled powder. This problem is a result of a spring that sits under the index ball; the ball that indexes the shellplate as it spins with every handle pull. This forceful indexing can cause powder to fly out of cartridges or misaligned rounds that can be jammed into dies causing damaged brass or even worse, damaged dies. By simply trimming this spring and adding the Hit Factor Shellplate Bearing Kit, you can alleviate these issues. Not only does it resolve troublesome issues, it can also improve the tolerances of your rounds.

Trimming the Index Ball Spring

When I first purchased the Dillon 650 several years back, I called Dillon regarding this issue and they recommended trimming the Index Ball Spring (Part #: 13997). The most IMPORTANT part of this process is to trim in small increments. Even though Dillon offers a replacement spring, it will cost you $10.44 with shipping.

In the below steps, the numbers in parentheses reference the part numbers in the Dillon 650 platform assembly diagram.

Step 1

Raise the Platform to Expose the Set Screw

Lower the handle to raise the platform to expose the main shaft (24) set screw (23).

Step 2

Remove the Shellplate Bolt

With the setscrew (23) loosened it will allow the shellplate bolt (3) to be removed.

Step 3

Remove the Ejector Wire and Shellplate

With the shellplate bolt (3) removed take off the ejector wire (4) and shellplate (6).

With the shellplate (6) off this will reveal the index ball (16).

Step 4

Remove the Index Ball and Index Ball Spring

Pop the index ball (16) out to allow removal of the index ball spring (17). A small allen wrench will do the trick.

With the index ball spring (17) out trim the spring in small increments.

*REMEMBER trim the spring in small increments. After each trim reinstall all components and test the shellplates indexing until the indexing is smooth.

Step 5

Installing the Hit Factor Dillon 650 Shellplate Bearing Kit

The Hit Factor bearing kit is a roller bearing unit that is sandwiched between two washers that sits in between the shellplate and shellplate bolt. This component allows for the shellplate bolt to be tightened providing for better support of the shellplate. This snug fit allows for less runout and a more consistent priming. Also, another advantage of this add-on is that it will not void your Dillon warranty since you are not modifying any of the original components. You can buy the bearing set from Hit Factor.

Source: https://downwindoutdoors.com/2015/02/dillon-650-powder-spill-fix/

0 Response to "Dillon 650 Flare Without Powder Feed"

Post a Comment